StatCounter

Sunday, August 14, 2022

Seal installer - GMC motorhome rear hub grease seal

Saturday, January 8, 2022

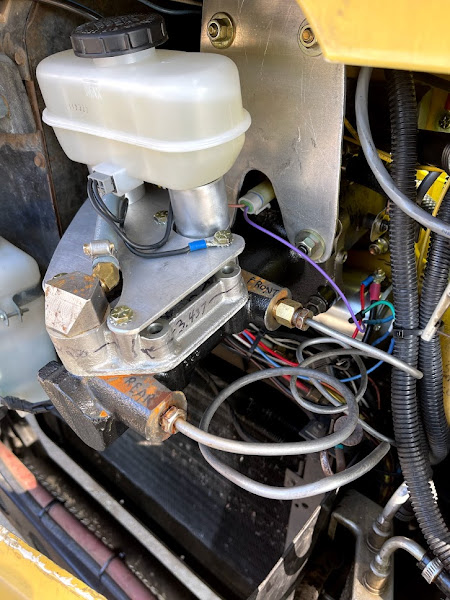

Hydromax and a GMC motorhome

Sunday, August 15, 2021

Long pilot oring adapter fitting for Hydromax

Thursday, December 10, 2020

GMC Motorhome brake booster comparison OEM vacuum, Hydroboost and Hydromax

Top to bottom Hydromax, Hydroboost with 40mm master, and OEM Vacuum booster

OEM vacuum booster

Hydroboost with 40 mm master cylinder

Hydromax with 2" master cylinder

http://1999southwind.com/DOWNLOAD/Bosch%20HydroMax%20Booster%20Manual.pdf

Hydromax manual link

Brake pressure from Hydromax

2" Hydromax master with reservoir removed. Built like a "P30" master

Booster poppet valves

Hydromax master at assembled length. Volume ratio between sections 1 to 1

Hydromax rod does come out and a few styles are available or make what you want. New grommets are available.

Hydromax is different than Hydroboost in that the hydraulic flow path can have

no restriction on the outlet, not a power beyond deal. Need a separate engine

driven pump on the GMC or some kind of dual section pump. Relatively huge

volume from the large master should satisfy all disk brakes with big pressure.

Backup electric pump on primary flow failure.

Thursday, June 18, 2020

Kiln control retrofit

Original control was two switches with high low off for each element. No temperature control at all. It required close watching.

New control kit has two SSR's a type K thermocouple and a ramp and step control. From Amazon https://www.amazon.com/gp/product/B07YN5YLS6/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Thursday, February 27, 2020

EDM test with Dave and Roy

Redesign with a linear actuator for ram

Saturday, January 11, 2020

Copper chill weld repair

Tuesday, December 17, 2019

Manganese Steel Safe repair

Here it is when I picked it up. Took two of their forklifts to lift it.

It weighs 4,400 lbs by the scale at my work. Front axle 2,710 lbs rear 6,480 lbs

To unload it was hooked to my ash tree and I drove out from under it. My neighbor got a huge kick out that process. Then I dragged it into the garage and stood it up.

Here it is refinished but without the locks working. It was short one dial and the other was fubar. I looked for years for reasonably priced dials that fit on a square shank like the spindles on the locks had. I gave up

The door rotates to open kind of like an artillery breech. The are two bolts that keep the door from rotating when it is locked.

Lock plate with two combination locks covers removed and a three movement time lock. Either combination lock will open it and any time movement. Redundancy on these. Combo locks are indirect drive so drilling the spindles to get it open wouldn't do any good. Spindles are tapered and also made of Manganese steel. Pounding on tapered spindle would only make it tighter. These Yale time lock movements became kind of a standard. New movements are available in mechanical and electronic versions and would fit right in this case.

Back of lock plate pin on lever actuates dog clutch that operates bolt mechanism. Time locks inhibit the combo locks until they time out.

Dog clutch, spindles on inside of door

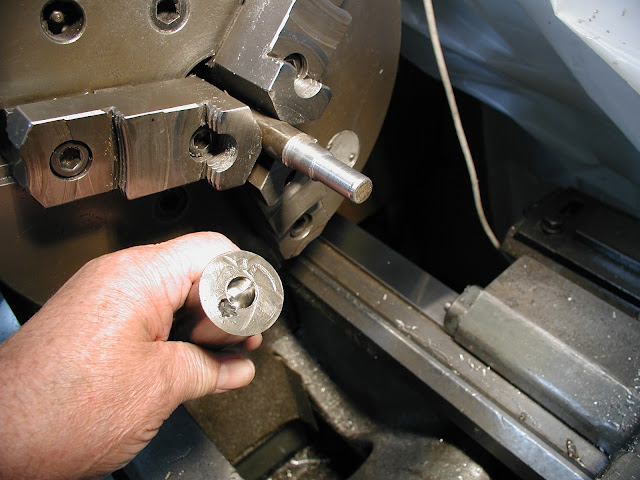

Combination lock spindles had a external square shank that the original dial fit on. We were missing one dial and the other was fubar. My plan was to adapt available modern dials with a 5/16x 40 threaded stem. To do this we drilled the original spindles partway with a 1/2" carbide spade bit and pressed in a piece of mild steel that could be drilled and tapped.

We got Sargent and Greenleaf dials which fit the original dial rings. Notice the spindle taper.

Checking for runout. The locks have a little adjustment for alignment and they turned out fine.

I made a lever out of a crank by bending with heat and welding in an extension.

Locks fixed with new dials. Operation is locks set the dog clutch to operate the bolts by turning the crank then the lever rotates the door to open.

Covers not on the combo locks in this picture. The covers can only be removed and installed by another combination setting.